Line Stops can be performed on most any type of pipe, ranging from carbon steel to PVC.

- CMLC, PCCP, SCCP, RCP Pipe

- Steel Cylinder

- Carbon Steel

- Ductile Iron

- Cast Iron

- Copper

- PVC

- Transite (AC pipe)

- Sewage

- Crude Oil

- Gasoline

- Water

- Steam

- Natural Gas

- Wastewater

Line Stops are used to temporarily shut down a pipeline system to complete modifications or repairs. They allow a system to operate as usual without any interruption of service. Line Stops can be performed on almost any kind of pipe with pressures up to 900 psi @ 100º F.

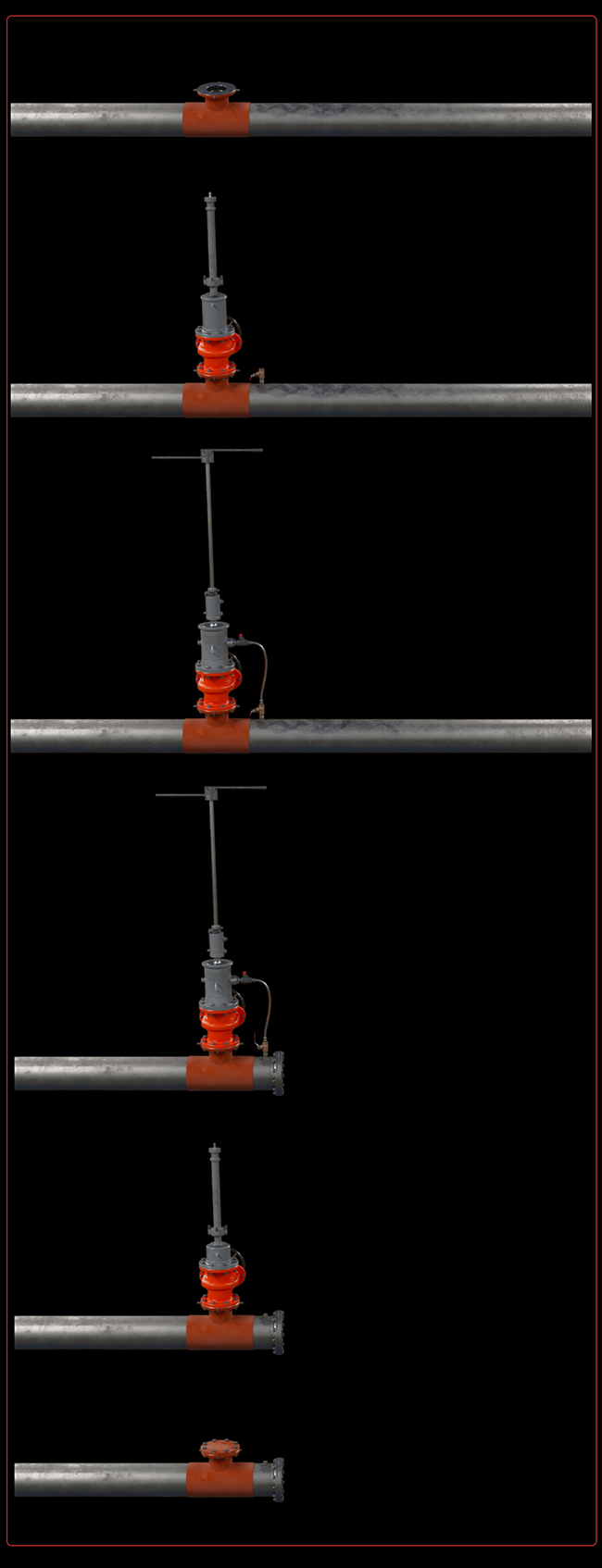

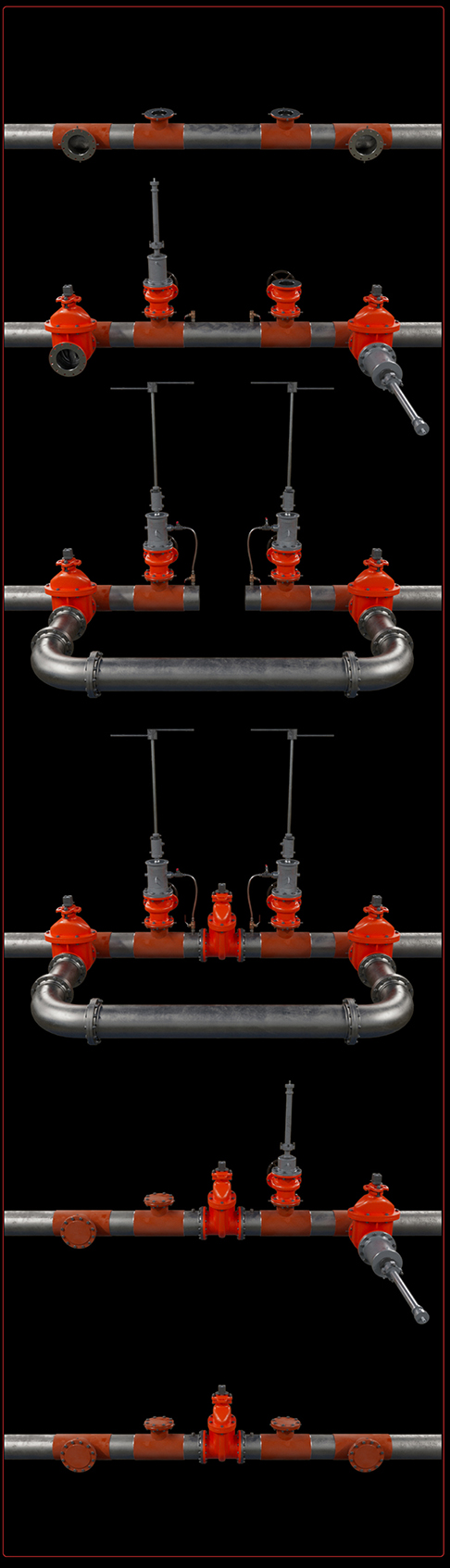

The Line Stop operation consists of a special flanged fitting, a temporary valve, and our actuator. The fitting is installed and tested, the temporary valve is installed, and the hot tap is completed. After the hot tap, we install the line stop actuator and insert the stopping head into the line.

When the necessary work has been accomplished, the stopping head is removed, and the completion plug is set. The completion plug seals at the flange on the fitting and allows us to remove our temporary gate valve. A blind flange is installed and the operation is complete.

Single Line Stop

Double Line Stop as External Bypass

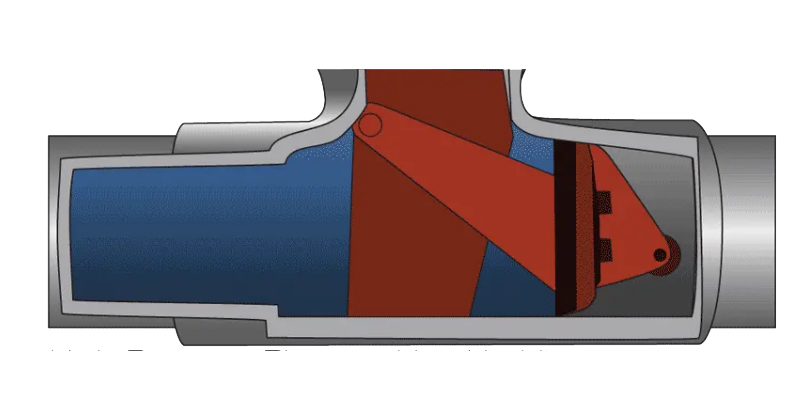

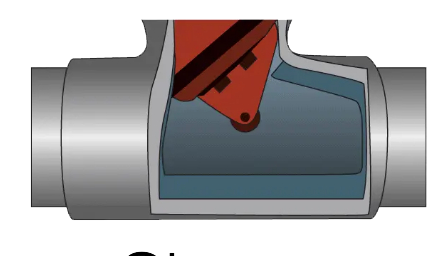

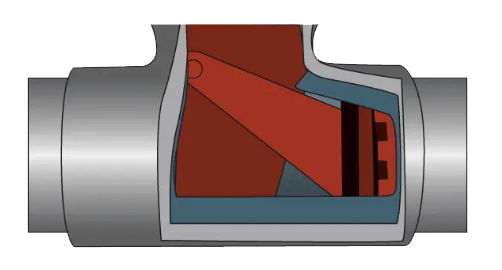

THE LINE STOPPING HEAD

The Koppl Pipeline Services High Pressure Plugging Head can perform line stops on various products with pressures up to 900 psig at 100° and temperatures up to 375° at 300 psig. The head is inserted into the line with our line stop actuator. When the pivot wheel contacts the bottom of the pipe, the head and sealing element roll into position and creates a seal, allowing you to perform work downstream.

High Pressure Plugging Head holding pressure in blue shaded area.

KopplStop™ Small Line Stop Fitting Equipment & Fittings

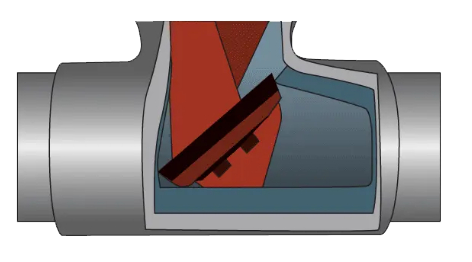

LINE STOP HEAD INSERTION

Step 1

The KopplStop™ Line Stopping Head is being inserted into the line. When the wheel reaches the bottom of the pipe, the head will pivot and roll into position.

Step 2

The KopplStop™ Line Stopping Head has reached the bottom of the pipe and is now rolling into position. The seal will gradually be created as the sealing element touches the interior wall of the pipe.

Step 3

The head and sealing element are now in its final position and a seal has been created. The pipeline will be bled off and the modification can begin

BARREL STYLE LINE STOPS

Barrel Style Line Stops are another method used to stop off pipelines. This method allows line stops to be performed on lines that may have scale or other type of corrosion build up on the inside wall, or when the inside diameter is uncertain. Barrel Style Line Stopping heads create their seal on the cut that is made when we complete the hot tap.

Typical Mueller™ Line Stop Fittings use a threaded completion plug to create a primary seal, with an O-ring used for a secondary seal. A gasket and blind flange is installed to complete the fitting.

Using special by-pass cylinder stoppers, service can be maintained while a new line is added. The old line can then be moved or capped off with no loss of product or interruption of service.

KopplStop™ Line Stop Fitting

- Flange Line Stop Fittings for steel pipe

- Size-on-Size and Reducing Branch

- KopplStop™ Dutchman Fitting for placement onto a standard flange

- QT Style Line Fittings for steel pipe

- Stainless Steel Bolt-On Style Line Stop Fittings available for many types of pipe

Mueller™ Line Stop Fittings Supplied by Koppl

Koppl QT Style Line Stop Fittings

Contact

Contact your local Koppl Pipeline Services representative.

Give us a call today to see what process can offer the best solution to your need.

- (323) 888-2211

- (323) 888-2232

Koppl Pipeline Services honors a legacy that has lasted for generations by bringing time-honored standards of quality and service to a modern age.

CCL#844802

AZCL#ROC216719

NVCL#0060642

HI#CT-31595